|

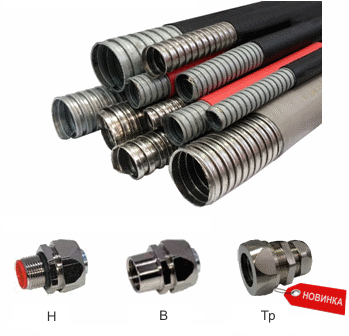

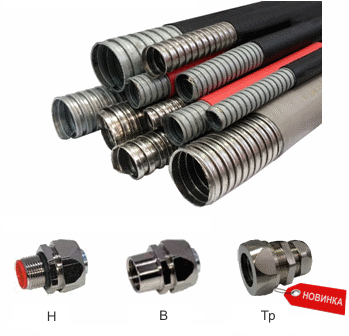

Gas-tight plastic sheathed flexible metal conduit ГЕРДА-МГ (ТУ 4833-011-76960731-2008)

Connector for the flexible metal conduit ГЕРДА-СГ (ТУ 1690-020-45416838-2008)

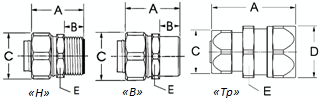

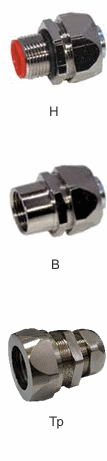

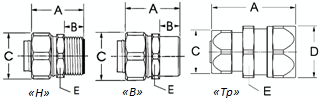

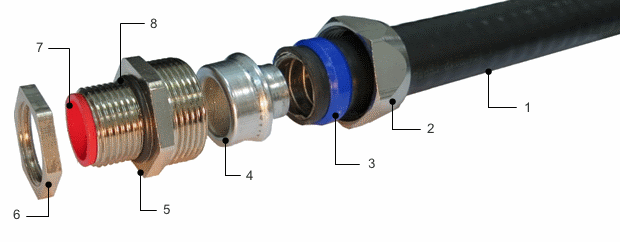

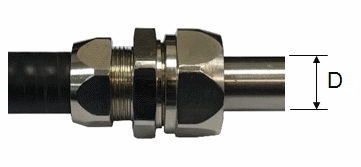

Design of the connectors ГЕРДА-СГ

Н - male thread; В - female thread; Tр - collet (on a pipe)

Technical characteristics

Minimal temperature of installation of the gas-tight metal conduits:

- -35°С for modification "нг-HF-ЭХЛ",

- -30°С for modification "нг-LS-ЭХЛ", "нг-LS-ЭХЛ-М",

- -25°С for modification "Тнг", "ХЛ",

- -15°С for other modification

Operation temperature of the gas-tight metal conduits:

- -70°...+80°С for modification "нг-HF-ЭХЛ",

- -70°...+70°С for modification "нг-LS-ЭХЛ", "нг-LS-ЭХЛ-М",

- -60°...+125°С for modification "Тнг",

- –50°...+200°С for modification "Тнг-T",

- -50°...+105°С for modification "т",

- -60°...+80°С for modification "ХЛ", "нг-ХЛ", "нг-LS-ХЛ",

- -50°...+50°С for modification "нг-HF", "нг-HFLTx",

- -60°...+50°С for modification "нг-HF-ХЛ",

- -50°...+80°С for other modification

Operation temperature of the connectors:

от -60°...+80°С

Climatic design B, installation category 1-5 (as per GOST 15150). Application is admissible in all macroclimatic areas, including tropics.

Ingress protection is rated up to IP67

All modifications of the metal conduit are resistant to sunlight (tested by method 211-1 of GOST 20.57.406-81). The maximal resistance to ultraviolet has been noted for a sheath of black colour, and also for modifications of "ЗГ", "HF", "T"

The sheath is tested for puncture by voltage of 6 kV acc. to GOST 2990-78

"M" – a sheath resistant to oil, gasoline and diesel fuel (tested acc. to GOST IEC 60811-2-1-2011),

"X" – chemical resistance of the sheath to acids and alkalis,

"ЗГ" – sheath with increased hardness resistant to bites of rodents, ants and termites

Various colours of the sheath. A needed colour is to be specified in an order code.

Warranty period of operation - 1 year from the date of installation, but no longer than 24 months from the date of production.

Service life is not less than 15 years from the date of production.

ГЕРДА-MГ gas-tight metal conduit is intended for protection of a cable, wires, flexible hoses against chemical and mechanical damage, influence of moisture and sunlight. ГЕРДА-МГ serves for the open and hidden laying in and out of rooms, channels, tunnels, trenches, can be applied in explosive zones of all classes. It is allowed to use the metal conduit for transportation of liquid, powdery and loose substances.

ГЕРДА-СГ connector allows fixing a metal conduit reliably on electric equipment (junction boxes, pipes, covers of devices, cable trays, etc.) – at the same time creating between them a grounding chain and providing IP67 degree of protection against dust and water.

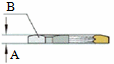

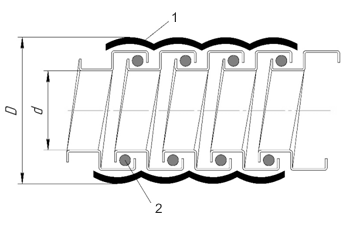

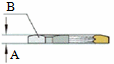

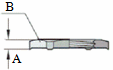

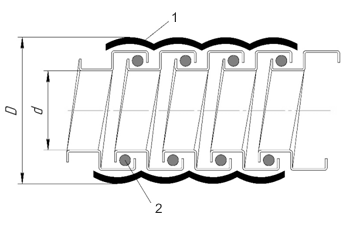

Design of the flexible metal conduit ГЕРДА-МГ

The flexible metal conduit is made of a galvanized (standard) or stainless steel tape (modification "Н") over which a protective polymeric sheath is imposed (see figure 1). The polymeric sheath provides full tightness of the metal conduit, protects from harmful effects of environment and considerably increases rupture strength. Available materials of the sheath are specified in table 2.

Between turns of the steel tape a cotton yarn is laid for sealing. The metal conduit is available in the following modifications:

- "П" (increased strength) – from thicker metal tape which provides higher rupture strength;

- "ХЛ" (cold-resistant) – for operation temperature down to -60°C;

- "ЭХЛ" (for extremely frigid climate) – for operation temperature down to -70 °C;

- "Т" (heat resistant) – for operation temperature up to +200°C;

- "М" (oil resistant) – with a sheath resistant to oil and gasoline;

- "Х" chemical resistance to acids and alkalis;

- "ЗГ" (protection against rodents) – with a sheath of increased hardness resistant to bites of rodents, ants and termites. It pro-vides the maximal resistance to abrasion which is essential for underground laying. It also resistant to ultraviolet and sunlight. Excellent chemical resistance against many acids and alkalis.

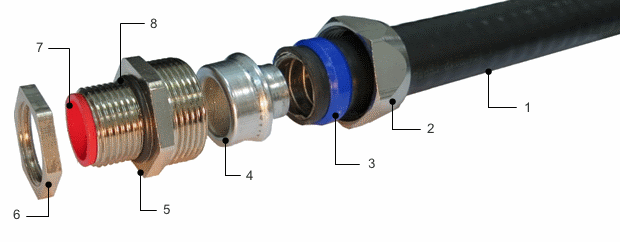

Design of the connectors

ГЕРДА-СГ connectors are made of the nickelized brass. On a way of connection to electric equipment the connectors are subdivided into the following types:

- "Н" — with male connecting thread. In addition it is possible to order a nut: flat (GP) or equipotential (GE) – see table 5;

- "В" — with a female connecting thread;

- "Тр" — on-pipe design (see figure 3). No thread on the pipe is required.

Connecting thread of a connector can be metric or tapered inch thread NPT (see table 5).

Picture 1. Design of gas-tight metal conduit ГЕРДА-МГ

(1 - Protective sheath; 2 - Sealing cotton yarn.)

| Table 1. Dimensions of ГЕРДА-МГ gas-tight metal conduit |

Metal conduit

Standard / of increased strength («П») or of stainless steel ribbon («Н») |

| Nominal diameter (Dn), mm |

Diameter d (inner) not less, mm |

Diameter D (outer) no more, mm |

Minimal bend radius, mm |

Rupture strength, kgs |

Mass of 100 m, kg |

Number of meters in one coil (1) [max. length], m |

| 15 |

13,9 |

21,3 |

65 / 75 |

25 / 80 |

28 / 31 |

50 [100] |

| 16 |

14,9 |

21,5 |

70 / 80 |

25 / 80 |

30 / 32 |

50 [100] |

| 18 |

16,9 |

24,3 |

80 / 90 |

25 / 85 |

33 / 36 |

50 [100] |

| 20 |

18,7 |

26,4 |

80 / 90 |

30 / 100 |

36 / 39 |

50 [90] |

| 22 |

20,7 |

27,0 |

100 / 110 |

30 / 100 |

37 / 40 |

50 [80] |

| 25 |

23,7 |

33,2 |

100 / 110 |

35 / 110 |

42 / 47 |

50 [70] |

| 32 |

30,4 |

40,8 |

140 / 150 |

45 / 130 |

65 / 71 |

50 [50] |

| 35 |

33,5 |

43,0 |

150 / 160 |

45 / 130 |

70 / 76 |

50 [50] |

| 38 |

36,4 |

46,8 |

160 / 180 |

50 / 150 |

82 / 90 |

50 [50] |

| 40 |

38,5 |

48,5 |

170 / 190 |

50 / 150 |

88 / 95 |

50 [50] |

Note:

- (1) – a minimal batch for ordering - 50 m. The producer may ship pieces less than 50 meters long, but no more than 20% of the whole batch

- – ГЕРДА-СГ connectors are available for the metal conduits highlighted with grey color only

| Table 2. Designation and operational temperature of the flexible metal conduit ГЕРДА-МГ depending on material of the sheath |

| Designation |

Description of material and properties of the metal sleeve sheath |

Operational temperature, °C |

| - (without designation) |

PVC plastic compound. |

-50°…+80°С |

| ХЛ |

PVC plastic compound of increased frost resistance. |

-60°…+80°С |

| т |

PVC plastic compound of increased heat resistance. |

-50°…+105°С |

| нг |

PVC plastic compound of low combustibility (fire retardant). |

-50°…+80°С |

| нг-ХЛ |

PVC plastic compound of low combustibility and increased frost resistance. A metal conduit with the нг-ХЛ cover is very flexible. |

-60°…+80°С |

| нг-LS |

PVC plastic compound with low smoke and gas emission. |

-50°…+80°С |

| нг-LS-ХЛ |

PVC plastic compound with low smoke and gas emission, increased frost resistance. |

-60°…+80°С |

| нг-LS-ЭХЛ |

PVC plastic compound with low smoke and gas emission, for extremely frigid climate. |

-70°…+70°С |

| нг-LS-ЭХЛ-М |

PVC plastic compound with low smoke and gas emission, for extremely frigid climate, oil and gasoline resistant. |

-70°…+70°С |

| нг-HF |

Halogens free polymer compound. |

-50°…+50°С |

| нг-HF-М |

Halogens free polymer compound, oil and gasoline resistant. |

-50°…+50°С |

| нг-HF-ХЛ |

Halogens free polymer compound with increased frost resistance. |

-60°…+50°С |

| нг-HF-ХЛ-М |

Halogens free polymer compound with increased resistance to frost, oil and gasoline. |

-60°…+50°С |

| нг-HF-ЭХЛ |

Halogens free polymer compound for extremely frigid climate. |

-70°…+80°С |

| Тнг |

Thermo-elastomer of low combustibility with increased abrasion resistance. |

-60°…+125°С |

| Тнг-М |

Thermo-elastomer of low combustibility, oil and gasoline resistant with increased abrasion resistance. |

-60°…+125°С |

| Тнг-Т |

Thermo-elastomer of increased heat resistance and low combustibility, with increased abrasion resistance. The sheath is less flexible than «Tнг». |

-50°…+200°С |

| нг-LSLTx |

PVC plastic compound with low smoke and gas emission which produces combustion products of low toxicity. |

-50°…+80°С |

| нг-HFLTx |

Halogens free polymer compound with low toxicity of combustion products. |

-50°…+50°С |

| нг-HF-ЗГ |

Halogen free polymer compound of increased hardness. Resistant to rodents, ants and ter-mites. Increased chemical resistance. Maximum resistance to abrasion and UV. |

-50°…+80°С |

| Х |

Polymer compound of increased chemical resistance to acids and basics. |

-50°…+80°С |

Note:

All metal conduits are resistant to sunlight (UV). The most resistant to UV are metal conduits with a sheath of black colour, with a sheath from halogen-free composition (HF), from thermoplastic elastomer (T), with a sheath resistant to rodents (ЗГ).

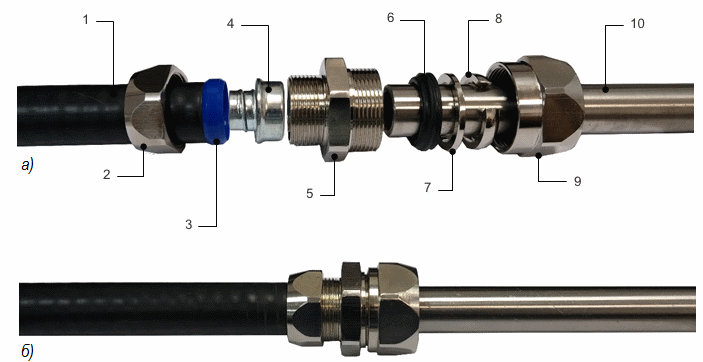

Figure 2. Design of ГЕРДА-СГ connector with male thread ("Н"). Connector ("B") has a female thread on the base (5).

(1 - Gas-tight metal conduit ГЕРДА-МГ; 2 - Connector nut; 3 - Polymeric sealing ring; 4 - Grounding bush; 5 - Connector base; 6 - Additional nut for fastening on electric equipment (it is ordered separately); 7 - Polymeric insert protect-ing cable of a damage; 8 - The rubber O-ring.)

Sequence of the connector assembling (see figure 2)::

- put the connector nut (2) and polymeric sealing ring (3) on the metal conduit (1);

- screw the grounding bush (4) into the metal conduit;

- screw the connector base (5) into the electric equipment case;

- Screw the connector nut (2) on the connector base (5) by hand, then tighten it with the wrench by 1-2 turns. The tightening torque should not exceed 15 N m.

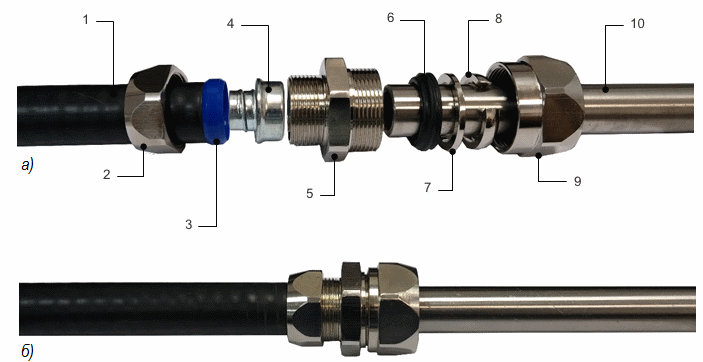

Pipe connector ГЕРДА-СГ-Tр

ГЕРДА-СГ-Tp connector allows to attach the gas-tight metal conduit ГЕРДА-МГ to a pipe easily without a need in threading on the pipe (see figure 3). The connector fastens on a pipe very firmly thanks to a collet ring (8). Tightness of the connection is provided by the elastomeric sealing ring (6). Available types of the connectors and corresponding pipe diameters are specified in table 4.

Figure 3. ГЕРДА-СГ-Tp connector for pipes. There is no need in threading on the pipe

- a) disassembled state (

1 - Gas-tight metal conduit ГЕРДА-МГ; 2 - Connector nut; 3 - Polymeric seal-ing ring; 4 - Grounding bush; 5 - Connector base; 6 - Sealing ring; 7 - Washer; 8 - Collet ring; 9 - Colet ring nut; 10 - Pipe.)

- b) assembled state

Designation used while ordering ГЕРДА-МГ metal conduit TU 4833-011-76960731-2008:

| ГЕРДА-МГ |

- |

|

- |

|

- |

|

- |

|

ТУ 4833-011-76960731-2008 |

|

|

1 |

|

2 |

|

3 |

|

4 |

|

- Nominal diameter (Dy), mm:

- 15

- 16

- 18

- 20

- 22

- 25

- 32

- 35

- 38

- 40

ГЕРДА-СГ connectors are available for the metal conduits highlighted with bold only

- Material of the metal tape:

- "no index" - galvanized steel

- "П" - galvanized steel of increased strength

- "Н" - stainless steel

- Polymeric sheath material (see Table 2):

- "no index"

- "ХЛ"

- "т"

- "нг"

- "нг-ХЛ"

- "нг-LS"

- "нг-LS-ХЛ"

- "нг-LS-ЭХЛ"

- "нг-LS-ЭХЛ-M"

- "нг-HF"

- "нг-HF-М"

- "нг-HF-ХЛ"

- "нг-HF-ХЛ-M"

- "нг-HF-ЭХЛ"

- "Тнг"

- "Tнг-M"

- "Tнг-T"

- "нг-LSLTx"

- "нг-HFLTx"

- "нг-HF-ЗГ"

- "Х"

- Colour of protection sheath (black - by default):

- "no index" - black

- "С" - blue

- "Ж" - yellow or orange

- "Б" - white or grey

- "З" - green

- "K" - red or pink

- "Kн" - brown

Другие цвета – по запросу

| Designation example for order |

Metal conduit description |

ГЕРДА-МГ-16-П-нг-ХЛ-С

ТУ 4833-011-76960731-2008

|

Gas-tight metal sleeve made of galvanized steel of the increased strength, Dn=16mm, in PVC sheath of blue colour, low combustibility, increased frost resistance. Operational temperature of –60 ° … +80 °C, installation at a temperature down to minus 25°C. |

ГЕРДА-МГ-22-нг-HF-ЗГ

ТУ 4833-011-76960731-2008

|

Gas-tight metal conduit made of galvanized steel of standard strength, Dn=22mm, in a sheath of halogen free polymeric composition of increased hardness. The sheath resistant to rodents, ants and termites, with increased chemical resistance, maximal resistance to abrasion and UV. Operational temperature: –50 … +70 °C, installation at a temperature down to minus 15°C. |

| Table 3. Primary application areas of ГЕРДА-МГ metal conduits depending on their execution type |

|---|

| Execution type |

Primary application area of ГЕРДА-МГ metal conduit |

— (w/o designation),

ХЛ,

т,

Х

|

For single laying in constructions and manufacturing facilities. Group laying is recommended only in outdoor electrical installations and production rooms where the service personnel is present just periodically. |

нг,

нг-ХЛ,

Тнг,

Тнг-М,

Тнг-Т |

For group and single laying in open constructions, platforms, galleries, production rooms. |

нг-LS,

нг-LS-ХЛ,

нг-LS-ЭХЛ,

нг-LS-ЭХЛ-М |

For laying in indoor electrical installations, and also in buildings, constructions and the closed cable constructions. |

нг-HF,

нг-HF-М,

нг-HF-ХЛ,

нг-HF-ХЛ-М,

нг-HF-ЭХЛ,

нг-HF-ЗГ |

For laying in indoor electrical installations, and also in buildings and constructions with mass stay of people, including multipurpose high-rise buildings and building complexes. |

нг-LSLTx,

нг-HFLTx |

For laying in buildings of child care, preschool and educational institutions, specialized nursing and disabled people homes, hospitals, in sleeping blocks of educational institutions and child care facilities. |

Connection to the equipment

(Н - male thread; В - female thread; Tр - collet (on a pipe))

Designation used while ordering ГЕРДА-СГ connector

ТУ 1690-020-45416838-2008

| ГЕРДА-CГ |

- |

|

- |

|

- |

|

ТУ 1690-020-45416838-2008 |

|

|

1 |

|

2 |

|

3 |

|

- Nominal diameter (Dn), mm:

For metal conduits of Dn = 15, 18, 20, 32, 38 mm - connectors are not available!

- Connection to the equipment:

- "Н" - male thread

- "В" - female thread

- "Тр" - collet (on a pipe)

- Type and the size of the connecting thread (see table 5):

- "no index" - For collet connection «Тр» without a thread

- "М" - metric (with pitch 1,5)

- "К" - inch taper thread NPT (type K acc. to GOST 6111-52)

Designation example

for order |

Connector description |

ГЕРДА-СГ-16-Н-М20х1,5

ТУ1690-020-45416838-2008 |

Tight metal sleeve connector of Dn=16mm (ГЕРДА-МГ-16), with an external carving of M20x1,5 |

ГЕРДА-СГ-22-Тр

ТУ1690-020-45416838-2008

|

Tight metal sleeve connector of Dn=22mm (ГЕРДА-МГ-22) for accession to a pipe with an outer diameter of 24,5... 28,0 mm. There is no need for a pipe carving cutting. |

| Table 4. Admissible outer pipe diameter for «Tр» connector |

| Pipe connector designation |

Admissible outer pipe diameter D, mm |

| ГЕРДА-СГ-16-Тр |

19,5...22,0 |

| ГЕРДА-СГ-22-Тр |

24,5...28,0 |

| ГЕРДА-СГ-25-Тр |

31,4...34,2 |

| ГЕРДА-СГ-35-Тр |

39,5...42,9 |

| ГЕРДА-СГ-40-Тр |

47,9...51,5 |

ГП - Flat nut; ГЭ - Equipotential nut - serves for creation of reliable electric contact between the con-nector and a case of electric equipment. At screwing the sharp cloves of the equipotential nut will cut paint off the housing wall and get in direct contact to the bare metal of the case.

Designation used while ordering additional nut

ТУ 1690-020-45416838-2008

| |

- |

|

ТУ 1690-020-45416838-2008 |

| 1 |

|

2 |

|

- Type of the additional nut for ГЕРДА-СГ connector (see table 5):

- "ГП" - Flat nut

- "ГЭ" - Equipotential nut (for metric thread М only)

- Type and the size of the connecting thread (see table 5):

- "М" - metric (with pitch 1,5)

- "К" - inch taper thread NPT (type K acc. to GOST 6111-52)

| Designation example for order |

Nut description |

ГП-К1/2″

ТУ1690-020-45416838-2008 |

Flat nut for connector ГЕРДА-СГ-16-Н-K1/2" |

ГЭ-М25х1,5

ТУ1690-020-45416838-2008 |

Equipotential nut for connector ГЕРДА-СГ-22-Н-М25х1,5M |

| Table 5. |

| For gas-tight metal conduit |

Order code for

ГЕРДА-СГ connector

Н — male (outer thread)

В — female (inner thread)

Тр — on-pipe

М — metric thread(1)

К — inch taper thread NPT(2)

|

ГЕРДА-СГ connector (3) dimensions, mm

|

Flat nut "ГП"

|

Equipotential nut "ГЭ"

|

| Order code for ГП nut |

Dimensions(3),mm

|

Order code for ГЭ nut |

Dimensions(3),mm

|

Inner

diameter, mm |

A |

B |

Key C |

Key E |

Key D |

А |

Key В |

А |

Key В |

| ГЕРДА-МГ-16 |

ГЕРДА-СГ-16-Н-М20х1,5 |

13,9 |

37 |

13 |

29 |

27 |

- |

ГП-М20х1,5 |

3 |

24 |

ГЭ-М20х1,5 |

3,7 |

24 |

| ГЕРДА-СГ-16-В-М20х1,5 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-16-Н-К1/2″ |

ГП-К1/2″ |

4 |

27 |

- |

- |

- |

| ГЕРДА-СГ-16-В-К1/2″ |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-16-Тр(4) |

58 |

- |

30 |

36 |

36 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-МГ-22 |

ГЕРДА-СГ-22-Н-М25х1,5 |

18,5 |

40 |

15 |

35 |

33 |

- |

ГП-М25х1,5 |

3,5 |

30 |

ГЭ-М25х1,5 |

4,5 |

30 |

| ГЕРДА-СГ-22-В-М25х1,5 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-22-Н-К3/4″ |

ГП-К3/4″ |

4 |

32 |

- |

- |

- |

| ГЕРДА-СГ-22-В-К3/4″ |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-22-Тр(4) |

60 |

- |

36 |

41 |

46 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-МГ-25 |

ГЕРДА-СГ-25-Н-М32х1,5 |

23,8 |

46 |

15 |

45 |

43 |

- |

ГП-М32х1,5 |

4 |

41 |

ГЭ-М32х1,5 |

5 |

41 |

| ГЕРДА-СГ-25-В-М32х1,5 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-25-Н-К1″ |

ГП-К1″ |

7 |

36 |

- |

- |

- |

| ГЕРДА-СГ-25-В-К1″ |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-25-Тр(4) |

66 |

- |

46 |

46 |

50 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-МГ-35 |

ГЕРДА-СГ-35-Н-М40х1,5 |

31,8 |

52 |

16 |

54 |

52 |

- |

ГП-М40х1,5 |

5 |

46 |

ГЭ-М40х1,5 |

6 |

50 |

| ГЕРДА-СГ-35-В-М40х1,5 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-35-Н-К1.1/4″ |

ГП-К1.1/4″ |

7 |

46 |

- |

- |

- |

| ГЕРДА-СГ-35-В-К1.1/4″ |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-35-Тр(4) |

72 |

- |

55 |

55 |

60 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-МГ-40 |

ГЕРДА-СГ-40-Н-М50х1,5 |

36,8 |

56 |

18 |

63 |

60 |

- |

ГП-М50х1,5 |

5 |

55 |

ГЭ-М50х1,5 |

6,2 |

60 |

| ГЕРДА-СГ-40-В-М50х1,5 |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-40-Н-К1.1/2″ |

ГП-К1.1/2″ |

7 |

55 |

- |

- |

- |

| ГЕРДА-СГ-40-В-К1.1/2″ |

- |

- |

- |

- |

- |

- |

| ГЕРДА-СГ-40-Тр(4) |

74 |

- |

65 |

65 |

70 |

- |

- |

- |

- |

- |

- |

1 - Metric thread М corresponds to GOST 24705-2004 (ISO 724:2003) with thread pitch of 1,5

2 - thread corresponds to Russian thread K acc. to standard GOST 6111-52

3 - Provided for information purposes only. The manufacturer may change dimensions without prior notice

4 – Admissible diameter of a pipe for the on-pipe connector is to be found in Table 4

|

+7 495 755 88 45

+7 495 755 88 45