We are always open for mutually beneficial cooperation

Gas detection system SKZ-12-Ex-01.M

Certifications:

|

SKZ-12-Ex-01.M features:

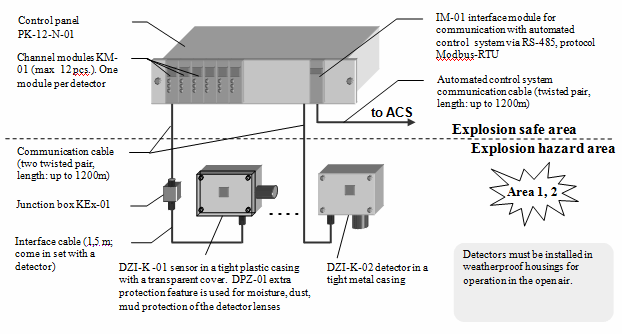

Application: the system is used for measuring hydrocarbon vapor pollution level in buildings and in the open air. This gas detection system is a stationary automatic quick-response (I-1 type) continuous-action multi-channel gas analyzer, which consists of a PK-12-N-01 control panel and explosion-proof (explosion protection type 2ExeIIT4) infra-red ДЗИ-К-01 gas detectors (plastic casing) or DZI-К-02 gas detectors (metal casing). DZI-К-01 detector is connected to the control panel via an interface cable and КЕх-01 terminal box. DZI-К-02 detector is connected directly to the communication cable by means of terminals mounted inside the detector. The control panel is designed as a standard 19″ crate which is to be mounted in a cabinet (with min. ingress protection IP20) located in non Ex-hazardous are. It comes complete with a set of КМ-01 channel modules whereby one module is connected to one detector (maximum of 12 channel modules). Gas detectors are to be installed in an area where the air pollution level should be measured. Depending on a type of gas the detector is adjusted to, a special lettering is put at the end of the detector type: NG — for oil gases, PG — for natural gases. A two twisted pair cable is used for data exchange between the control panel channel module and the detector. The first twisted pair is used for RS-485 interface communications, the second one provides detector power supply. Each channel module of the control panel features three relay controlled outputs — warning and fault alarm, error signal. IM-01 interface module provides communication (Modbus RTU protocol) with an high level automated control system. One such module is installed in the control panel. Maximum 32 control panels may send data through one RS-485 line, so the high level system can receive data from maximum of 384 detectors. Checkup and calibration of the measuring channel, relay thresholds setup (for warning and fault alarms) is done by switching control panel channel module to „Service” mode, in which case relay actuation is disabled throughout the service works period and „channel in service mode” status is transferred to the automated control system via Modbus. Special testing stand СТ-3 is used for laboratory checkup and calibration of metering channels of the system. The testing stand is complete with software which enables input and storage of calibration tables and output of comprehensive info on measuring channel status, etc. On the detectors and channel modules there are digital indicators that display the measured gas pollution level in % of NKPR (LFL — lower flammability level) of the air-gas mixture, LED indicators of warning and fault alarms which are ON whenever a set threshold is reached. Whenever a measuring channel operation error is detected the digital indicator of the channel module displays a fault error code and the red „FAULT” LED is ON. For operation in the open air DZI-K-01 and DZI-K —02 detectors are mounted in weather protection housings KKZ-01. Extra protection unit DPZ-01 may be used for moisture, dust and mud protection of optical cell of DZI-K-01 detector at indoor installations.

Structure of description for purchase orderGas detection system SKZ-12-Ех-01.M — K/M/GR/DI — ... — KKZ-DPZ where:

Remarks: by default the system is complete with IP-01 interface module; DZI-K −01detector is shipped complete with KEx-01 terminal box. Example of product description in a purchase order: Gas detection system SKZ-12-Ех-01.M-5/1NG/P/ ½-7/2NG/P/ ½-7KKZ-3DPZ Interpretation of the description: SKZ-12-Ех-01.M —

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V.Latsisa st., 17, bldg. 1

Fax: +7(495) 755 88 46

+7 495 755 88 45

+7 495 755 88 45